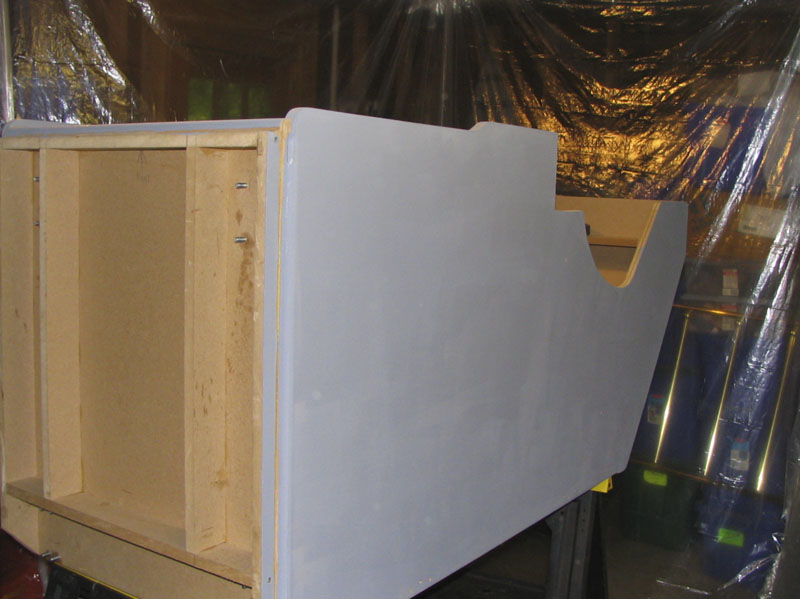

Paint sure does go on nicer than primer. Something that is kind of cool is how the paint spreads once it has been rolled on. Initially I can see roller marks. Once the paint has sat for a while it sort of spreads out and forms kind of a sheet of paint. It is very smooth. I painted it and sanded between coats. I laid down 2 full coats to start off.

I fully sanded the thing and put in my heat vent (a slot hole cut at the union of the very top and the angled piece). This was to allow the escape of heat from the computer and screen. All was going well Too well…(thrown in for dramatic effect)

I fully dusted off all the residual paint powder, and got the floor swept up all nice and tidy in my little paint booth. I was about to do my final coat of black. I wanted to paint more of it at eye level so I decided to put the cab up on saw horses. I have gotten pretty good at moving this thing around by myself, so I leaned it back and set the top back of the cabinet on one saw horse. I lifted the bottom with the other saw horse in front of me so I could push it into place with my foot when I got it lifted. I have done this several times without issue. BUT! What I did not see coming is that paint makes smooth surfaces very slick. The whole thing slipped right off the sawhorse and went crashing onto the floor. Everything seemed to be slow motion. I watched the side and the top vibrating apart and another board from somewhere flying away spiraling through the air. After a lot of screaming, yelling, and a violent toss and slam of my closest sawhorse, I walked out of the garage with a sick stomach and in tears. I am sorry if that is just not manly, but it happened. I have been working on this thing for 5 full months now. I could not go in to see the full extent of the damage.

(AT) Do not let an object become more important than your family. Also, try not to let said object cause you to unleash anger in a way you might regret. Sure, I write this now 4 years after the fact, so I suppose it is easier to say, but it is something that I am more mindful of. The cabinet was a stupid piece of wood. But that stupid piece of wood consumed much of my thought back then. He knew it was important to me, but I exhibited something that was not within the realm of acceptable. As a dad, this is a moment that I regret. Your kids look at you for example and this was truly not an example that I wish to set. I knew it immediately. After I slammed the saw horse, I looked over at him. My son watched the whole thing. I was in a bad place. It was compounded by my actions. I got down on my knees and looked him in the eyes and apologized to him. He did not deserve that.

Back to the story

Back to the story

I finally got my nerve up. If you remember from early on, the top and angled back was glued into a channel. The MDF split straight up from the channel to the top on both sides. It seems to have followed the groove that was cut to hold the t-molding. So much of the area around this was just fractured into little tiny pieces. So, front to back it was completely separated at the top. The board that was to hold the Fluorescent light completely is gone (probably the flying piece). Near the back of the cab in the top left rear corner was severely dented in (probably the impact point) causing the MDF to separate into sheets. There are many other places that have stress fractures as well.

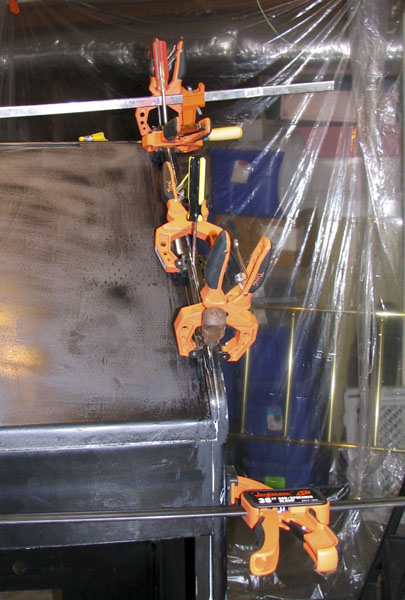

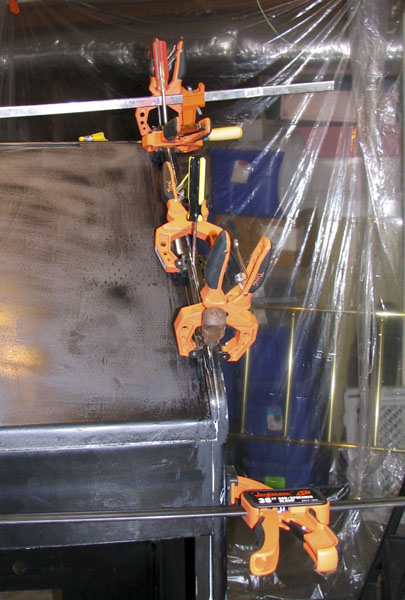

After some time of pulling myself back together, I started gluing the leaves of MDF back together. I figured that it would be better to start with rebuilding strength before trying to re-attach the top, back and side.  I spread the leaves apart and put as much glue in there as I could get and clamped it hard. After about a half hour I drenched the left crevasse with glue all the way from the front to the back. I used a paint mixer stick to spread the glue so both sides were solidly covered. I then clamped with 36 in clamps at the very front and back. Slowly I tightened the clamps and brought the top, and back together with the side. I put flathead screwdrivers into the t-molding groove to maintain the groove while everything was clamped. Then I clamped the full 3/4 inch lip. This way pressure could be put across the whole piece. I spent the next 15 minutes wiping up glue drippings.

I spread the leaves apart and put as much glue in there as I could get and clamped it hard. After about a half hour I drenched the left crevasse with glue all the way from the front to the back. I used a paint mixer stick to spread the glue so both sides were solidly covered. I then clamped with 36 in clamps at the very front and back. Slowly I tightened the clamps and brought the top, and back together with the side. I put flathead screwdrivers into the t-molding groove to maintain the groove while everything was clamped. Then I clamped the full 3/4 inch lip. This way pressure could be put across the whole piece. I spent the next 15 minutes wiping up glue drippings.

Down on the left side on the corner that will support the CP, that MDF has split but it is still tight. I am trying to decide if I want to split it further and re-glue it or to leave it as is and just t-mold it. If I do not split it, it will always be weak point. I will probably need to split and glue it

I think I may sue the sawhorse company for pain and suffering.

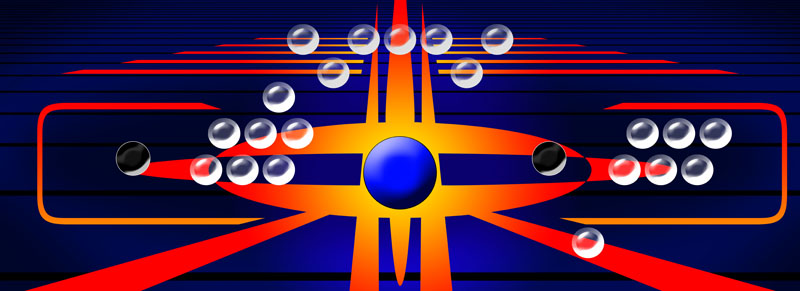

On a different note, I worked more on the marquee seeing as how I WASN’T PAINTING! I was playing around with different color treatments. I really like the blue direction.